// Industries //

Rubber and Tyre

For manufacturers of vehicle tyres and other products made out of rubber, the consequences of pieces of metal accidentally making their way into the production process can quickly become costly. Damage and downtime are potential risks, but we have the right metal detection systems to minimise them.

Metal Detector

- Metal particles reduce productivity, increase costs Downtimes due to machine incidences reduce the productivity of rubber processing machines like extruders or calenders.

- Metal particles are one of the main reasons for screw damages in extruders or damages to the rolls of calenders.

- However: metal particles in the processed material are unexceptional

- In production lines with high machine utilization, metal detectors have been standard equipment for long time already.

Metal Detector

- Detect all kinds of metallic contaminations, even if they are embedded in the product

- Reduce costs caused by machine damage and production downtimes

- Increase production efficiency

- Guarantee product quality

- Protect against customer complaints

- Provide a rapid return on investment

TU separable tunnels

- Standard metal detector for tire industry

- Robust and firm construction design guarantees high interference signals particularly for the typical production conditions in the rubber and tire industry

- Easy integration in belt conveyor systems without the need to open the belt

- Auto-Balance function can compensate material conductivity and surrounding influences less risk of false reactions can be set on-site, individually to plant specific conditions

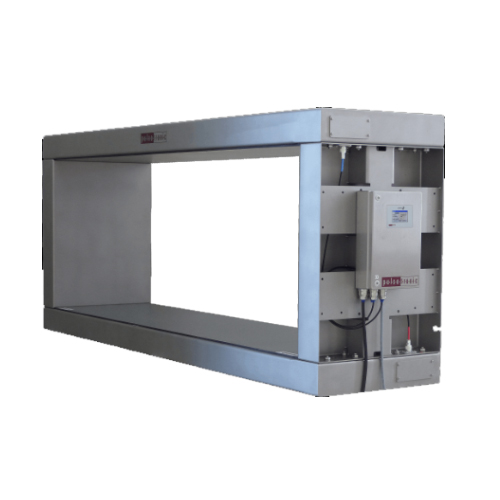

BD series tunnel detectors

Tunnel metal detector for installation in belt conveyor systems and material chutes with high requirements regarding scanning sensitivity

Metal detector for installation in belt conveyors

- Reliable - in Process and Detection

- Durable - in Technology and Performance

- Conforming - in Design and Data management